An Overview of the Major Forms of HVAC Ductwork

October 3, 2023

Supply ductwork allows air to enter different house parts, while return ductwork gets air back to the HVAC for heating or cooling. Both ductwork variations are critical to your HVAC performance. For example, inefficient ductwork wastes significant energy. Below are the common ductwork forms your contractor may mention during system design or renovation.

Rigid duct materials do not bend or change shape easily, meaning they do not deform easily. Another advantage is that rigid duct materials do not puncture or tear easily, and duct punctures or tears can lead to air leakages and inefficient cooling.

Below are the main forms of rigid ductwork:

Galvanized steel and aluminum are common materials for rigid ductwork. The material is relatively inexpensive too. Here are further advantages of metal ductwork:

Metal ductwork is easy to clean but attracts dust so ensure you clean yours regularly.

Fiberglass is a mixture of glass fibers and resin. The core material of fiberglass ductwork is metal, as is the case with metal ductwork. However, fiberglass material lines the metal as an insulation layer. Here are some benefits of fiberglass ductwork:

The silent nature of fiberglass ductwork makes them excellent for use in buildings where noise is unwanted. For example, fiberglass ductwork is common in commercial buildings where noise is not required.

Don't forget to clean your fiberglass ductwork regularly to reduce the risk of mold growth.

Fiberglass is the main material for fiberboard ductwork. The duct is essentially fiberglass with a foil laminate covering. The foil covering protects the fiberglass from moisture absorption and damage. Below are some benefits of fiberboard ducts:

Note that HVAC contractors discourage fiberboard ductwork in humid areas. The combination of fiberboard and high humidity encourages mold growth.

Flexible ductwork easily bends without damage. Flexible ductwork is primarily a wire coil inside durable plastic, and the insulation layer—which can be different materials—prevents heat transfer between the air inside and outside the ductwork.

Flexible ductwork has several advantages that make it attractive to homeowners. First, flexible ductwork installation is relatively affordable; the material is inexpensive, and installing it is easy. Contractors won't have difficulty installing the ductwork in tight spaces as they would with rigid ductwork, which leads to fast installation times.

Secondly, flexible ductwork does not contaminate the air flowing through it like some rigid duct materials. The duct material, primarily plastic, is resistant to mold and rust that often foul indoor air. In short, your flexible duct will likely stay clean and avoid fouling your indoor air for a long time.

Rigid and flexible are the main forms of ductwork, but you can also get semi-rigid ones. For example, HVAC manufacturers can fashion aluminum into thin sheets that are a bit flexible.

Semi-rigid ductwork is great for those who want the best of both worlds—rigid and flexible ductwork. For example, installers can work with semi-rigid ductwork in tight spaces, but it is still durable since it's metal.

Briarwood Heating & Cooling has years of HVAC experience. Our skilled technicians install, service, and repair your HVAC system and get your home comfortable. Contact us for a quote and enjoy our professional services.

Rigid Ductwork

Rigid duct materials do not bend or change shape easily, meaning they do not deform easily. Another advantage is that rigid duct materials do not puncture or tear easily, and duct punctures or tears can lead to air leakages and inefficient cooling.

Below are the main forms of rigid ductwork:

Sheet Metal

Galvanized steel and aluminum are common materials for rigid ductwork. The material is relatively inexpensive too. Here are further advantages of metal ductwork:

- They are easy to clean.

- They are easy to install due to their lightweight nature.

- Their non-porous surfaces discourage mold growth.

- They are relatively durable.

Metal ductwork is easy to clean but attracts dust so ensure you clean yours regularly.

Fiberglass

Fiberglass is a mixture of glass fibers and resin. The core material of fiberglass ductwork is metal, as is the case with metal ductwork. However, fiberglass material lines the metal as an insulation layer. Here are some benefits of fiberglass ductwork:

- They are relatively silent compared to metal ductwork.

- They are relatively energy efficient due to the fiberglass lining that absorbs sound.

- They are resistant to condensation.

The silent nature of fiberglass ductwork makes them excellent for use in buildings where noise is unwanted. For example, fiberglass ductwork is common in commercial buildings where noise is not required.

Don't forget to clean your fiberglass ductwork regularly to reduce the risk of mold growth.

Fiberboard

Fiberglass is the main material for fiberboard ductwork. The duct is essentially fiberglass with a foil laminate covering. The foil covering protects the fiberglass from moisture absorption and damage. Below are some benefits of fiberboard ducts:

- They are relatively inexpensive.

- They minimize heat loss or gain since fiberglass is an insulation material.

- They minimize HVAC noise since fiberglass absorbs sound.

Note that HVAC contractors discourage fiberboard ductwork in humid areas. The combination of fiberboard and high humidity encourages mold growth.

Flexible Ductwork

Flexible ductwork easily bends without damage. Flexible ductwork is primarily a wire coil inside durable plastic, and the insulation layer—which can be different materials—prevents heat transfer between the air inside and outside the ductwork.

Flexible ductwork has several advantages that make it attractive to homeowners. First, flexible ductwork installation is relatively affordable; the material is inexpensive, and installing it is easy. Contractors won't have difficulty installing the ductwork in tight spaces as they would with rigid ductwork, which leads to fast installation times.

Secondly, flexible ductwork does not contaminate the air flowing through it like some rigid duct materials. The duct material, primarily plastic, is resistant to mold and rust that often foul indoor air. In short, your flexible duct will likely stay clean and avoid fouling your indoor air for a long time.

Semi-rigid Ductwork

Rigid and flexible are the main forms of ductwork, but you can also get semi-rigid ones. For example, HVAC manufacturers can fashion aluminum into thin sheets that are a bit flexible.

Semi-rigid ductwork is great for those who want the best of both worlds—rigid and flexible ductwork. For example, installers can work with semi-rigid ductwork in tight spaces, but it is still durable since it's metal.

Briarwood Heating & Cooling has years of HVAC experience. Our skilled technicians install, service, and repair your HVAC system and get your home comfortable. Contact us for a quote and enjoy our professional services.

Your furnace has been keeping your family warm through Michigan winters for years. But lately, something's off. Maybe it's strange noises, climbing energy bills, or that one bedroom that never warms up. You're wondering: Is it time to replace my furnace? After nearly 30 years serving Rochester Hills, Shelby Township, Sterling Heights and surrounding areas; we have completed thousands of furnace installations, we know this decision isn't always or simple. Here's our honest guide to help you decide. The Quick Answer Most furnaces should be replaced between 15-20 years . But age isn't everything. The best time to replace is when: Repair costs exceed 50% of replacement cost Energy bills have increased 15-30% over recent years Your comfort is suffering (cold rooms, constant breakdowns) Safety concerns arise (yellow flames, CO risks) Let's break down the seven clear signs it's time for a new furnace. 7 Signs It's Time to Replace Your Furnace 1. Your Furnace Is 15+ Years Old Even if it "still works," furnaces over 15 years old are operating on borrowed time. Furnaces over 15 years old are: 40% more likely to need emergency repairs 25-35% less efficient than modern systems Costing you $400-600 extra per year in energy The efficiency gap: Your 2005 furnace might have been 90% efficient when new. Today's models hit 95-98% efficiency with variable-speed operation your old system never had. Real savings: A homeowner with a 2,000 sq ft home can save $400-600 annually upgrading from an 80% system to a 96% AFUE furnace. 2. Repair Costs Are Adding Up The 50% Rule: If a single repair costs more than 50% of a new furnace, replacement usually makes more sense—especially if your system is 15+ years old. The "death spiral" pattern: Winter 2023: Blower motor - $450 Winter 2024: Ignitor and sensor - $580 Winter 2025: Control board - $720 Total: $1,750 over 3 years That $1,750 could have been a down payment on a new system with a 10-year warranty. When repair makes sense: Furnace under 10 years old Single isolated problem Repair under $500 Well-maintained system You're moving within 2-3 years 3. Energy Bills Keep Climbing What's normal: 3-5% annual increases (utility rates) Red flag: 15-30% increases over 2-3 years with similar usage Why it happens: Heat exchangers corrode, blower motors wear down, sensors drift, and debris accumulates. Your furnace runs longer to heat your home, burning more gas. 4. Uneven Heating Throughout Your Home "The upstairs is freezing while the main floor is a sauna." Sound familiar? Why old furnaces create hot/cold spots: Single-stage operation: They're either blasting at 100% or completely off Fixed-speed blowers: Can't adjust to different zones Improper sizing: Oversized systems short-cycle and create temperature swings Ductwork issues: Aging furnaces can't compensate anymore Modern solution: Variable-speed, two-stage furnaces run longer at lower speeds, distributing heat evenly throughout your home. 5. Frequent Breakdowns Listen, we like that you keep us on speed dial when something goes wrong. However, If you're calling for repairs more than once every 2-3 years, you're in the "failure zone." Why breakdowns accelerate: Parts become discontinued/scarce One failure stresses other components Diagnosis becomes more complex The emergency premium: Furnaces break during polar vortexes, not mild October afternoons. Emergency repairs cost 50-80% more due to overtime rates, rush parts, and high demand. 6. Strange Noises You've Never Heard Furnaces should be relatively quiet. New sounds often signal impending failure. Loud banging at startup: Delayed ignition (gas building up then igniting). Can crack heat exchangers and cause CO leaks. Common on 12+ year systems. Constant rattling/vibrating: Blower wheel imbalance or failed motor mounts. Repair costs $400-900—usually not worth it on 15+ year furnaces. Squealing/screeching: Blower motor bearings failing. Gets louder over weeks, eventually fails completely (usually during the coldest week). Rumbling after burner shuts off: Potentially cracked heat exchanger. This is a safety emergency. Shut off your furnace and call us immediately at 248-299-8126. Modern furnaces are remarkably quiet. If yours sounds like a jet engine, it's time for an upgrade. 7. Yellow or Flickering Burner Flame (SAFETY CRITICAL) What's healthy: Steady, blue flame (perhaps small yellow tip) What's dangerous: Mostly yellow/orange flame, flickering, or visible soot What it means: Incomplete combustion, which causes: Carbon monoxide production (safety risk) Wasted energy (higher bills) Soot buildup (damages components) Common causes on 15+ year furnaces: Cracked heat exchanger Dirty burners (years of buildup) Improper air mixture Failing gas valve CARBON MONOXIDE WARNING: If you notice: Yellow flame Soot around furnace Family headaches or flu-like symptoms CO detector alarming SHUT OFF YOUR FURNACE IMMEDIATELY and call us at 248-299-8126. This is a genuine emergency. We typically recommend immediate replacement for furnaces with yellow flames over 15 years old, as repair costs approach new system costs. The Repair vs. Replace Decision Tree REPAIR Makes Sense: ✅ Under 10 years old ✅ Single, clear issue ✅ Repair under $500 ✅ Well-maintained ✅ Energy bills stable ✅ Moving within 2-3 years REPLACE Makes Sense: ✅ 15+ years old ✅ Multiple/recurring issues ✅ Repair over $1,000 ✅ Bills increasing significantly ✅ Uneven heating ✅ Staying 5+ years ✅ Safety concerns High-Efficiency vs. Standard: Worth It? Quick comparison for 2,000 sq ft home: 80% AFUE (Standard): Installed: $3,800-4,800 Annual heating: ~$1,450 10-year total: ~$18,300 96% AFUE (High-Efficiency): Installed: $5,500-7,000 Annual heating: ~$1,085 10-year total: ~$16,350 Net savings over 10 years: $1,950+ Payback: 4-5 years High-efficiency also provides: Better comfort (variable-speed = even temps) 50-70% quieter operation Better air filtration Higher home resale value Our recommendation: For homeowners staying 5+ years, high-efficiency systems almost always make financial sense AND provide dramatically better comfort. Financing & Incentives (2026) Financing: 0% for 18 months No prepayment penalties Federal Tax Credits: Up to $600 for 97%+AFUE furnaces Utility Rebates: DTE Energy: gas customers Up to $300 Consumers Energy: Up to $300 Total savings example: 97%AFUE furnace: $6200 Federal credit: -$600 Consumer Energy gas rebate: -$300 Net cost: $ 5300 or $294/month for 18 months (0% APR) with a minimum monthly payment for approved homeowners Why Choose Briarwood? 25+ Years Serving Rochester Hills We're your neighbors. Family-owned. Built on trust. Always here. Trane Comfort Specialist Elite dealer status with factory-extended warranties and advanced training. 4.9 Stars, 580+ Google Reviews Our reputation speaks for itself. 24/7 Emergency Support Real humans, real availability.

Furnaces 1. How often should I service my furnace? It’s recommended to have your furnace serviced annually, ideally before the heating season begins. Regular maintenance ensures efficient operation and extends the furnace's lifespan. Check out our coupons on Briarwood’s website for savings! 2. How do I know if my furnace needs repairs? Common signs include strange noises, uneven heating, high energy bills, frequent cycling on and off, or a yellow pilot light (if applicable). Call Briarwood if you notice these issues. 3. What size furnace do I need for my home? The size depends on your home’s square footage, insulation, climate, and energy efficiency. An HVAC professional can help to determine the correct size. If you are in need of an estimate to replace your furnace, Call Briarwood for a no cost estimate in your home. 4. What’s the average lifespan of a furnace? A well-maintained furnace typically lasts 15-20 years. Regular maintenance can help achieve or exceed this lifespan. 5. Should I upgrade to a high-efficiency furnace? High-efficiency furnaces (with AFUE ratings of 90% or higher) can lower energy bills and reduce your carbon footprint. Consider the upfront cost versus long-term savings when deciding. 6. What type of filter should I use for my furnace? The type depends on your furnace model and your indoor air quality needs. Pleated filters offer good filtration for most homes. Check the owner’s manual for compatibility. Another option is electronic air cleaners like the Aerus Air Scrubber designed by NASA. Humidifiers 1. Why do I need a humidifier? Humidifiers add moisture to dry indoor air, which can prevent dry skin, alleviate respiratory issues, and protect wooden furniture and floors from cracking. 2. What types of humidifiers work with furnaces? Furnace-compatible humidifiers include bypass, fan-powered, and steam humidifiers. Each type has its advantages; consult with Briarwood for a professional to determine the best option for your home. 3. How do I maintain my furnace humidifier? Included in your Furnace clean and check from Briarwood is cleaning your humidifier, drain lines and changing the evaporator pad. 4. What’s the ideal indoor humidity level in winter? Aim for 30-50% relative humidity. Levels below 30% can cause dry air, while levels above 50% may encourage mold and dust mites. 5. Can a humidifier damage my furnace? Properly installed and maintained humidifiers won’t damage your furnace. However, neglecting maintenance can lead to leaks or mineral buildup, potentially causing issues. 6. Do I need a humidifier if I have a high-efficiency furnace? High-efficiency furnaces often dry out the air more than older models. A humidifier can improve comfort, even in homes with modern heating systems. General Questions 1. Can I run my furnace and humidifier simultaneously? Yes, they are designed to work together. The furnace heats the air, and the humidifier adds moisture, improving overall comfort. 2. How do I know if my home is too dry? Signs of dry air include static electricity, dry skin, irritated sinuses, and cracking wood. A hygrometer can measure indoor humidity levels. 3. What should I do if my humidifier or furnace isn’t working? Check for common issues like power supply problems, clogged filters, or incorrect thermostat settings. If the problem persists, contact Briarwood Heating and Cooling to schedule one of our top notch technicians to repair your system. 4. Can I install a furnace humidifier myself? While it’s possible for handy homeowners, professional installation ensures proper setup and avoids potential issues. It may also preserve warranties. This FAQ is designed to address common questions and concerns related to furnaces and humidifiers. For more specific issues or guidance, consult Briarwood Heating and Cooling at 248-299-8126 . We have been proudly serving Rochester, Shelby Twp, Sterling Heights, Lake Orion and surrounding areas for over 25 years!

When it comes to maintaining the comfort and safety of your home, your boiler is one of the most vital components. It’s responsible for keeping you warm during the colder months and in some cases ensuring your hot water is always available. However, like any mechanical system, a boiler requires regular care to function optimally. One of the key aspects of this maintenance is the boiler clean and check. Here’s why these services are crucial for your boiler's performance, safety, and longevity. What Are Boiler Clean and Checks? A boiler clean and check involve a comprehensive maintenance routine performed by a professional technician. Call Briarwood Heating & Cooling of Rochester Hills to schedule a boiler expert to come to your home at 248-299-8126. This process typically includes: Cleaning: Removing dirt, dust, and debris from the boiler’s internal components. Inspection: Checking all parts of the boiler for wear, damage, and proper function. Testing: Ensuring the system operates efficiently and safely. Adjustments: Making necessary adjustments to optimize performance and efficiency. Why Regular Cleaning and Checking Are Essential Maximized Efficiency Over time, boilers can accumulate grime and soot, which can reduce their efficiency. A thorough cleaning removes these obstructions, allowing the boiler to operate more efficiently. This not only helps in reducing energy consumption but also lowers your utility bills, as a cleaner boiler uses less fuel to produce the same amount of heat. 2. Enhanced Safety A well-maintained boiler is a safe boiler. Regular clean and checks are crucial for identifying potential safety hazards such as: Carbon Monoxide Leaks: Carbon monoxide is a colorless, odorless gas that can be deadly. Regular checks help ensure that your boiler’s flue and ventilation are functioning correctly, reducing the risk of leaks. Gas Leaks: A professional can check for any gas leaks that might pose a safety risk. Faulty Components: Ensuring that all components are in good working order helps prevent dangerous malfunctions. Water leaks: A professional can check for water leaks before it causes damage to your home 3. Extended Lifespan Boilers are a significant investment, and regular maintenance helps protect that investment. By removing dirt and debris and fixing minor issues before they become serious problems, you can extend the lifespan of your boiler. This proactive approach can help you avoid costly replacements and repairs in the future. 4. Consistent Performance A clean and well-maintained boiler operates more reliably. Regular clean and checks help ensure that your boiler performs consistently, keeping your home warm and your hot water flowing without unexpected breakdowns. This reliability is especially important during the winter months when you depend on your boiler the most. 5. Lower Repair Costs Minor issues caught during routine maintenance are usually less expensive to fix than major problems that arise from neglect. By investing in regular clean and checks, you can avoid the higher costs associated with emergency repairs and significant breakdowns. When to Schedule a Boiler Clean and Check For optimal performance, it’s recommended to schedule a boiler clean and check at least once a year. The best time to arrange this service is before the heating season begins, so your boiler is ready to perform efficiently when you need it the most. However, if you notice any unusual noises, reduced efficiency, or other issues, it’s a good idea to schedule a check sooner. What to Expect During a Clean and Check During a boiler clean and check, a technician will typically: Clean the Boiler: Remove any accumulated soot, dust, and debris from the boiler’s components. Inspect: Examine key components such as the burner, heat exchanger, and flue for signs of wear or damage. Test: Ensure that the boiler operates efficiently and safely, checking for proper combustion and ventilation. Adjust: Make any necessary adjustments to improve performance and efficiency. Conclusion Regular boiler clean and checks are essential for maintaining the efficiency, safety, and longevity of your heating system. By investing in these routine services, you ensure that your boiler operates at its best, providing consistent warmth and hot water while minimizing the risk of costly repairs and safety issues. If it’s been over a year since your last boiler service, or if you’re experiencing any issues with your heating system, don’t wait—schedule a clean and check with a qualified professional today. Keeping up with this crucial maintenance will give you peace of mind and help ensure your home remains comfortable and safe throughout the year. Call the boiler experts at Briarwood Heating and Cooling at 248-299-8126 . We proudly have been serving Grosse Pointe, St Clair Shores and surrounding Oakland and Macomb County for over 25 years!

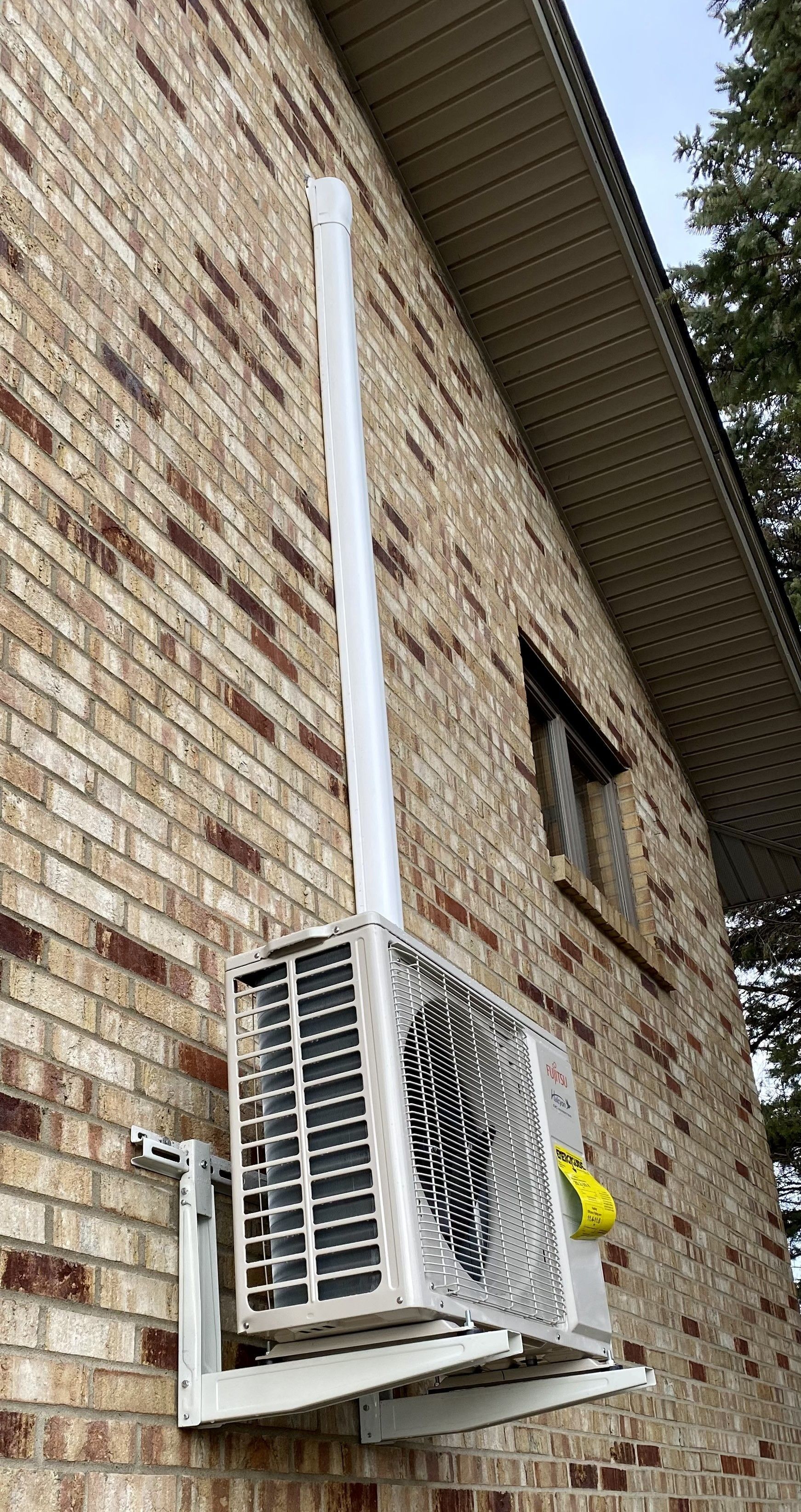

As energy efficiency and customizable climate control become increasingly important in today’s homes and businesses, mini split systems are emerging as a popular solution. These systems, known for their flexibility, efficiency, and ease of installation, offer a host of benefits that make them a standout choice for modern climate control. In this blog, we’ll explore the ins and outs of mini split systems and why they might be the perfect option for your heating and cooling needs. What is a Mini Split System? A mini split system, also known as a ductless mini split, is a type of heating and cooling system that does not require ductwork to distribute air throughout a space. Instead, it consists of two main components: an outdoor compressor/condenser and one or more indoor air-handling units. These units are connected by a conduit that houses the communication cable, liquid tubing, suction tubing, and a condensate drain. Key Benefits of Mini Split Systems 1. **Energy Efficiency** One of the most significant advantages of mini split systems is their energy efficiency. Traditional ducted systems can lose a significant amount of energy through the ductwork, but mini splits eliminate this issue by delivering air directly to the desired spaces. Additionally, many mini split systems are equipped with inverter technology, which allows the compressor to adjust its speed based on the cooling or heating demand, further enhancing efficiency and reducing energy consumption. 2. **Flexible Zoning** Mini split systems offer unparalleled flexibility when it comes to zoning. Each indoor unit can be controlled independently, allowing different rooms or zones to be set to different temperatures. This means you can cool or heat specific areas as needed, providing personalized comfort and reducing energy waste by not conditioning unused spaces. 3. **Easy Installation** Compared to traditional HVAC systems, mini splits are relatively easy to install. Since they don’t require ductwork, installation is less invasive and can be completed more quickly. The conduit between the outdoor and indoor units typically requires only a small hole in the wall, minimizing the impact on the building’s structure and aesthetics. 4. **Improved Air Quality** Mini split systems often include advanced filtration options that can help improve indoor air quality. These filters can capture dust, allergens, and other pollutants, providing cleaner air for your home or business. Additionally, because mini splits don’t use ducts, there’s no risk of dust and debris accumulating in ductwork and being circulated throughout the space. 5. **Quiet Operation** Mini splits are known for their quiet operation. The indoor units are designed to operate at low noise levels, making them ideal for bedrooms, offices, and other areas where noise might be a concern. The outdoor units are also generally quieter than those of traditional HVAC systems. Applications of Mini Split Systems 1. **Residential Homes** Mini split systems are an excellent choice for residential homes, particularly in situations where installing ductwork would be impractical or too costly. They are ideal for new additions, renovated spaces, or homes without existing ductwork. Homeowners can enjoy the benefits of efficient and customizable climate control without the need for extensive modifications to their property. 2. **Commercial Spaces** In commercial settings, mini splits offer a versatile and efficient solution for climate control. Offices, retail stores, restaurants, and other commercial spaces can benefit from the zoning capabilities, allowing different areas to be conditioned according to their specific needs. This can lead to significant energy savings and improved comfort for employees and customers. 3. **Specialty Applications** Mini split systems are also well-suited for specialty applications such as server rooms, workshops, and other spaces that require precise temperature control. Their ability to operate independently in different zones makes them ideal for maintaining specific environmental conditions. Conclusion Mini split systems represent a modern and efficient approach to heating and cooling, offering a range of benefits that make them a compelling choice for both residential and commercial applications. Their energy efficiency, flexible zoning, easy installation, improved air quality, and quiet operation set them apart from traditional HVAC systems. If you’re looking for a cost-effective and versatile solution for your climate control needs, a mini split system might be the perfect option for you. Call Briarwood Heating and Cooling today to schedule a no-cost estimate at 248-299-8126. We have been proudly serving Sterling Heights, Shelby Township, Rochester and surrounding areas for over 25 years!

If your air conditioner is not keeping up with the heat, it could mean you’re in need of air conditioning repair. Several factors could be contributing to the issue. Here are some common reasons why your AC could be struggling: ### 1. **Dirty or Clogged Air Filters** Air filters trap dust, dirt, and other particles to keep your indoor air clean. Over time, these filters can become clogged, reducing airflow and making it harder for your AC to cool your home. Regularly replacing or cleaning your filters can improve performance. ### 2. **Blocked or Closed Vents** Ensure that all vents and registers in your home are open and unobstructed. Furniture, curtains, or other objects can block airflow, preventing cool air from circulating properly. ### 3. **Thermostat Issues** Your thermostat might be incorrectly set or malfunctioning. Double-check the settings to ensure it’s set to "cool" and that the temperature setting is lower than the current room temperature. If the thermostat is faulty, it may need to be replaced. ### 4. **Dirty Coils** Both the evaporator coil (inside your home) and the condenser coil (outside your home) need to be clean for the AC to work efficiently. Dirt and debris on these coils can reduce their ability to absorb and release heat, making your system less effective. ### 5. **Low Refrigerant Levels** Refrigerant is essential for the cooling process. If the refrigerant levels are low, likely due to a leak, your AC won’t be able to cool effectively. Low refrigerant levels require professional attention to locate and fix the leak and recharge the system. ### 6. **Leaky Ductwork** Air leaks in the ductwork can result in significant loss of cooled air before it reaches your living spaces. This makes your AC work harder to achieve the desired temperature. Sealing duct leaks can improve efficiency and cooling performance. ### 7. **Inadequate Insulation** Poor insulation allows cool air to escape and warm air to enter, making it difficult for your AC to maintain a comfortable temperature. Insulating your home properly can help keep the cool air inside. ### 8. **Outdoor Unit Obstructions** The outdoor condenser unit needs sufficient airflow to release the heat it removes from your home. Ensure that there is no debris, vegetation, or other obstructions around the unit. ### 9. **Old or Inefficient AC Unit** If your air conditioner is old (typically more than 10-15 years), it may not be as efficient as newer models. Over time, components wear out and the system becomes less effective. Upgrading to a new, energy-efficient model can significantly improve cooling performance. ### 10. **High Outdoor Temperatures** During extreme heat waves, even a well-functioning AC might struggle to keep up. When outdoor temperatures are excessively high, your AC may not be able to maintain the desired indoor temperature. In such cases, additional measures like using fans and reducing heat-generating activities can help. ### 11. **Improperly Sized AC Unit** If your AC unit is too small for your home, it won’t be able to cool effectively, especially during peak heat. Conversely, an oversized unit may cycle on and off too quickly, failing to dehumidify the air properly. Proper sizing is crucial for optimal performance. ### Conclusion An air conditioner that isn’t keeping up can be due to a variety of reasons, from simple fixes like replacing a dirty filters to more complex issues like refrigerant leaks or an improperly sized unit. Regular maintenance and prompt attention to problems can help ensure your system runs efficiently. If you’ve checked these common issues and your AC is still struggling and in need of ac repair, call the professionals at BRIARWOOD HEATING AND COOLING ; 248-299-8126. We have been serving Shelby Township and Sterling Heights for over 25 years now!